Precision Molds, Excellence by Anbang.

After one year and five months, the Anbang family of high-precision vertical CNC machining centers is proud to welcome its newest member! As a pioneering force in the field of precision machining, the arrival of this state-of-the-art equipment highlights our relentless pursuit of technological advancement and represents a solid step forward in enhancing productivity and optimizing customer service quality.

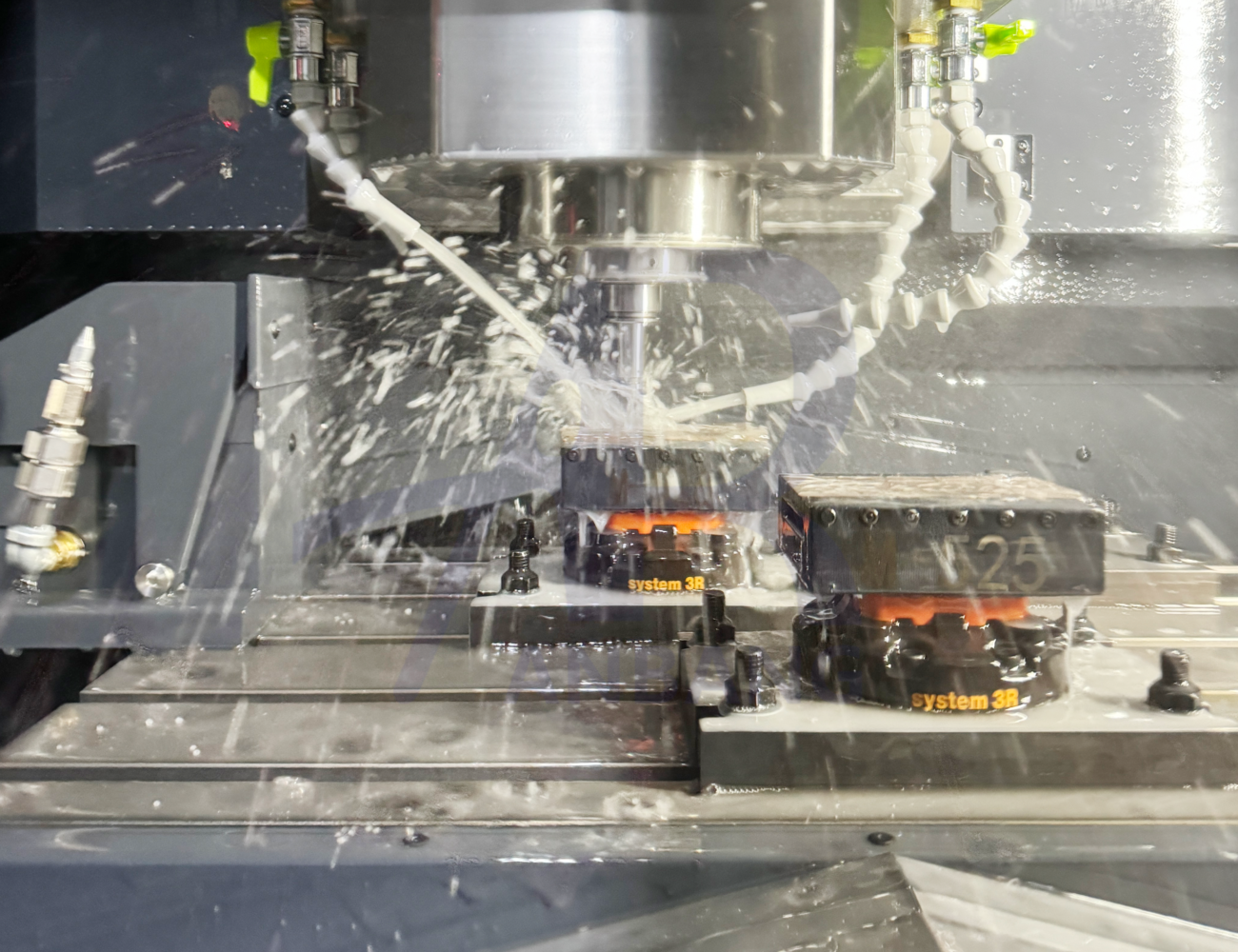

A Cutting-Edge Vertical 3-Axis Machining Center from Japan

Delivering Unparalleled Precision

Equipped with an advanced linear motor design and a 0.005-micron grating feedback system, this high-end machining center combines exceptional component temperature control technology to minimize process parameter adjustments caused by tool positioning errors or thermal deformation. It precisely measures tool lengths, achieving sub-micron accuracy and consistent repeatability. This ensures stable and predictable performance for cutting tools, spindle speeds, and machining depths, enabling Anbang to deliver precise, stable, repeatable, and highly consistent machining results for its customers.

Outstanding Efficiency

With ultra-fast operation speeds and exceptional cutting performance, this new addition significantly reduces production cycles and dramatically boosts productivity.

Flexible and Versatile Applications

Its broad range of applications, large travel capacity, and flexible spindle design make it highly practical for producing miniature mold components. It is the ideal precision equipment for mirror finishing and other high-precision machining tasks.

“A craftsman must sharpen their tools if they are to do their work well.”

The arrival of this new equipment further strengthens our production capabilities, enabling us to provide customers with even higher-quality precision molds. It is a testament to our commitment to meeting the ever-evolving demands of our diverse clientele.